3D printing – the future

The rapid development of 3D printing is changing the world of manufacturing, as more industries gain the ability to ‘print’ a variety of products. CSIRO is pushing the frontiers of 3D printing metals for a wide range of applications, through its Lab22 operation.

A 20-year old American girl previously diagnosed with a rare bone cancer (chondrosarcoma) received a life boost in 2017 through the implant of a customised sternum and partial rib-cage made from 3D printed titanium and a polymer.

This was the latest in a series of medical success stories from CSIRO’s additive manufacturing operations, achieved in collaboration with a medical implant company Anatomics, and the surgeons who performed the implants.

“CSIRO provides Australian companies with access to metal additive manufacturing, or 3D printing technologies that deliver competitive advantage through efficiency and productivity gains,” says Dr Daniel East, Director, CSIRO’s additive manufacturing centre Lab22.

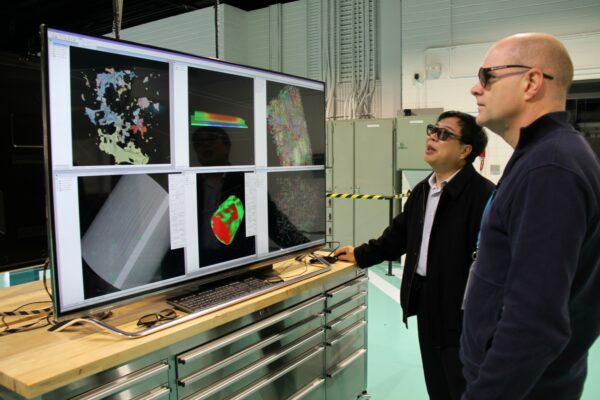

Above: Lab22 breaks down barriers for small business entry into 3D printing.

“Lab22 in Melbourne, is our $6 million additive manufacturing centre, with the latest technology enabling Australian industry to 3D print out of sand, titanium and other metals.” Apart from metallic 3D printing of titanium aluminium and the like, Lab22 offers advanced machining, surface engineering and laser treatments to improve profitability and performance.

Above: Industry can 3D print out of sand, titanium and other metals using Lab22 facilities.

“Our machines include powder bed, cold spray and blown powder approaches to introduce the raw materials, and can be used for a wide range of applications. Our designers can turn a new design idea into a testable prototype within a week.”

“What we’ve seen so far is the tip of the iceberg, as the range of materials and applications for 3D printing continue to expand at a staggering rate,” says Daniel.

What could 3D printing deliver in our cities?

3D printing is transforming manufacturing in a wide range of fields including medical, science, engineering, the arts and housing and construction.

Above: At Lab22, companies can explore and apply additive manufacturing technologies for big productivity gains.

As 3D printers get larger, so have the requests, with more companies targeting house construction in recent years. A number of companies advertise being able to build a 100 square metre house within 24 hours. In some cases, 3D printed house construction utilises a 360° robotic arm to feed mortar and insert electrical circuitry into the house structure.

While we don’t yet know the full extent of additive manufacturing (3D printing) applications at the Ginninderra sustainable urban development, “the potential is enormous” says Daniel.

“3D printing is changing our approaches to production, associated energy use and waste, and has the potential to totally transform the world of manufacturing in our cities of the future.”